Cemented Tungsten Carbide Hard Alloy Screw Cold Heading Dies Mian

Dies Forming Dies Mould

In standard parts industry, tungsten carbide cold heading dies need

to under great unit pressure in cold upsetting deformation process

, when a large degree of deformation and material hardness, units

of pressure up to 2000MPa more.

At the same time the metal flow intense, thus requiring tungsten

carbide cold heading dies have high strength, high hardness and

good fatigue resistance, in order to ensure the cold heading dies

under high pressure without breaking, deformation and wear

resistance.Tungsten carbide cold heading die raw material is

produced by powder metallurgy composite materials, which have high

hardness, wear resistance,life is several times and several hundred

times than ordinary cold heading die.

With carbide manufacturing standard tungsten carbide cold heading

die, not only have high dimensional accuracy of parts, but also

greatly improve the life of the cold heading die, can create good

economic and social benefits.

Grade List

| Grade and Application |

| Grade | Density (g/cm³) | Hardness (HRA) | Bend Strength (N/mm²) | Performance & Application Recommended |

| YG11 | 14.4 | 88.5 | 2600 | Forming of stamping dies for metal powders and nonmental powders |

| YG15 | 14 | 87.5 | 2800 | For fabricating drawing dies of steel tubesand rods under high |

| Compressibility ratio,punching ,stamping,forging tools under large

stress. |

| YG20 | 13.5 | 85.5 | 3200 | For fabricating of stamping dies for watch parts,spring plates of

musical |

| Instruments,battery jars, small sized stell balls,screws.screw caps |

| YG16C | 13.9 | 85.5 | 2900 | Impact resistance,hot & forging dies,etc. |

| YG18C | 13.7 | 84.5 | 3100 | Impact resistance forging dies,hot-press forging dies and rollers. |

| YG20C | 13.5 | 83.5 | 3300 | Dies for wear resistant or impact resistant application |

| YG22C | 13.3 | 83 | 3500 | Nut forming dies and high impact resistance forging dies |

| YG25C | 13.1 | 82.5 | 3600 | Stainless bolt header dies and rollers |

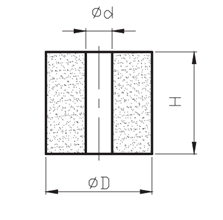

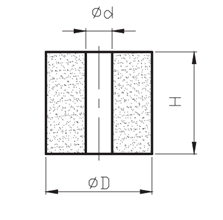

| Dimension |

| D | d | H |

| 10.0-44.0 | 1.5-6.0 | 20.0-60.0 |

| 32.0-50.0 | 6.2-10.0 | 32.0-60.0 |

| 40.0-40.0 | 11.4-15.0 | 20.0-60.0 |

| 40.0-+50.0 | 15.4-20.0 | 20.0-75.0 |

| 45.0-70.0 | 21.0-25.0 | 20.0-85.0 |

| 55.0-75.0 | 26.0-30.0 | 25.0-40.0 |

| 75.0-90.0 | 30.5-38.0 | 30.0-40.0 |

| 80.0-100.0 | 42.0-50.0 | 30.0-50.0 |

| 90.0 | 52.0 | 40.0 |

| 100.0 | 60.0 | 40.0 |

| 100.0 | 61.5 | 20.0 |

| 120.0 | 70.0 | 40.0 |

| 130.0 | 80.0 | 40.0 |

| 140.0 | 85.0 | 40.0 |

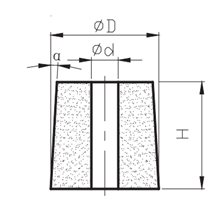

| Dimension | |

| d | D | H | α° |

| 20 | 9 | 22 | 1° 30° |

| 20 | 9.4 | 22 |

| 21 | 10.4 | 20 |

| 25 | 12.2 | 20 |

| 30 | 12.5 | 22 |

| 25 | 13 | 20 |

| 30 | 13 | 22 |

| 36 | 18.8 | 22 |

| 36 | 19.2 | 22 |

| 32 | 19.4 | 20 |

| 40 | 22 | 22 |

| 38 | 22.5 | 20 |

| 40 | 22.5 | 22 |

| 40 | 23.5 | 22 |

| 38 | 23.9 | 20 |

| 40 | 24.2 | 22 |

| 47 | 28.8 | 20 |

| 47 | 30.8 | 20 |

| 46 | 31.2 | 22 |

| 47 | 31.8 | 20 |

| Dimension |

| D | d | H | a° | D | d | H | a° |

| 14.0 | 2.1 | 15.0-30.0 | 20.0 | 30.0 | 8.4 | 25.0-54.0 | 20.0 |

| 16.0 | 2.1 | 15.0-30.0 | 30.0 | 10.0 | 14.0-20.0 |

| 14.0 | 3.1 | 15.0-30.0 | 28.0 | 10.2 | 25.0-54.0 |

| 16.0 | 3.1 | 15.0-30.0 | 30.0 | 10.2 | 25.0-54.0 |

| 14.0 | 3.9 | 15.0-35.0 | 40.0 | 11.9 | 30.0-40.0 |

| 16.0 | 3.9 | 15.0-35.0 | 40.0 | 12.0 | 10.0-14.0 |

| 16.0 | 4.5 | 10.0-20.0 | 40.0 | 14.0 | 14.0-20.0 |

| 16.0 | 4.7 | 15.0-35.0 | 45.0 | 17.5 | 14.0-20.0 |

| 18.0 | 4.7 | 20.0-35.0 | 45.0 | 19.5 | 20.0-30.0 |

| 20.0 | 6.5 | 20.0-42.0 | 50.0 | 21.0 | 20.0-30.0 |

| 22.0 | 6.5 | 10.0-42.0 | 60.0 | 24.0 | 25.0-30.0 |

| 30.0 | 8.0 | 10.0-20.0 | 60.0 | 26.5 | 25.0-30.0 | 12.0 |

| 26.0 | 8.4 | 25.0-54.0 | 70.0 | 32.0 | 25.0-30.0 |

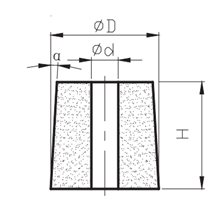

| Dimension |

| D | d | H | a° | D | d | H | a° |

| 13.0 | 2.8 | 30.0 | 90.0 | 30.0 | 6.4 | 30.0 | 90.0 |

| 16.0 | 3.8 | 30.0 | 30.0 | 6.4 | 55.0 |

| 16.0 | 3.8 | 40.0 | 36.0 | 8.2 | 55.0 |

| 22.0 | 3.8 | 50.0 | 40.0 | 10.0 | 55.0 |

| 16.0 | 4.6 | 30.0 | 45.0 | 10.0 | 55.0 |

| 22.0 | 4.6 | 50.0 | 60.0 | 13.8 | 60.0 |

Production Process

FAQ

Q1: How can I place order?

A1: You can contact us by email about your order details, or place

order on line.

Q2: How can I pay you?

A2: After you confirm our PI, we will request you to pay. T/T (HSBC

bank) and Paypal, Western Union are the most usual ways we are

using.

Q3: What’s the order procedure?

A3: First we discuss order details, production details by email or

TM. Then we issue you an PI for your confirmation. You will be

requested to do pr -epaid full payment or deposit before we go into

production. After we get the deposit, we start to process the

order. We usually need 7-15 days if we don’t have the items in

stock. Before production has been finished, we will contact you for

shipment details, and the balance payment. After payment has been

settled, we start to prepare the shipment for you.

Q4: How do you take care when your clients received defective

products?

A4: replacement. If there are some defective items, we usually

credit to our customer or replace in next shipment.

Q5: How do you check all the goods in the production line?

A5: We have spot inspection and finished product inspection. We

check the goods when they go into next step production procedure.