Customized Size Hole Diameter Tungsten Carbide Wire Drawing Dies

Wire drawing dies application

1. Nonfeerous wire, including copper, aluminium, electromagnetic

and stainless steel wire.

2. Platinum rhodium wire

3. Gold wire

4. Silver wire

5. Molybdenum, nickel, tined and so on non ferrous metal wires.

Cemented carbide is a composite material composed of a refractory

metal compound (hard phase) and a binder metal (bonded phase)

produced by powder metallurgy.

1. 100% raw material for production.

2. Hip sintered, reliable hardness, durable wear resistance

3. Various sizes, carbide grade and full types available

4. Competitive price with on-time delivery

5. Customized product as per drawing and small order

accepted,professional and in-time technical support

Grade List

| Grade | Co (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Applications |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 | Wire drawing dies for wear-resistance impact-resistance |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 |

| XC300 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 2600 |

| XC301 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 3200 |

| XC500 | 14.7-15.3 | 13.9-14.2 | 87.0-88.0 | 2600 | Stamping dies for impact-resistance |

| XC501 | 14.7-15.3 | 13.9-14.2 | 87.0-88.0 | 2800 |

| XC800 | 19.5-20.5 | 13.4-13.6 | 83.0-84.0 | 2600 |

| XC8001 | 19.5-20.5 | 13.4-13.6 | 83.0-84.0 | 3000 |

| XC900 | 23.0-23.5 | 13.1-13.4 | 82.5-83.5 | 2400 |

| XC901 | 23.0-23.5 | 13.1-13.4 | 82.5-83.5 | 2600 |

| Grade | Co+Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Applications |

| XCN61 | 16.0-17.0 | 13.5-14.0 | 83.5-84.5 | 3200 | Stamping dies for High temperature-resistance |

| XCN71 | 17.0-18.0 | 13.3-13.8 | 82.0-83.0 | 3000 |

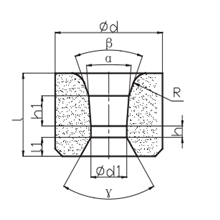

| Dimension |

| d | l | d1 | h | h1 | ll |

| 8 | 6 | 0.1-1.0 | 0.1-10.6 | 1.0-2.0 | 0.8-1.2 |

| 10 | 8 | 0.1-1.2 | 0.1-0.8 | 1.5-4.0 | 1.0-1.8 |

| 12 | 10 | 0.2-2.0 | 0.1-1.5 | 2.0-5.0 | 1.6-2.5 |

| 14 | 12 | 0.4-2.5 | 0.2-2.0 | 4.0-5.0 | 1.8-2.5 |

| 16 | 13 | 0.5-3.0 | 0.2-2.5 | 4.0-5.5 | 2.0-3.0 |

| 20 | 17 | 1.0-6.0 | 0.6-3.0 | 5.0-8.0 | 2.5-4.0 |

| 25 | 20 | 2.0-8.5 | 1.0-3.5 | 7.0-10.0 | 3.0-4.5 |

| 30 | 24 | 3.5-12.0 | 2.0-4.0 | 8.0-12.0 | 3.0-5.0 |

| Notice: α=8°10° 12° 14°16°18° β=40° 60° 90° γ=60° 75° 90° |

| Dimension | |

| ΦD | b | H | α | β | γ |

| 6.0-8.0 | 0..2 | 4.0-6.0 | 10° | 40° | 60° |

| 6.0-8.0 | 0.4-0.8 | 4.0-6.0 | 40° | * |

| 8.0-22.0 | 0.4-5.7 | 6.0-20.0 | 10°-14° | 40° |

| 8.0-26.0 | 0.4-8.0 | 6.0-16.0 | 16° | 40° |

| 30.0-140.0 | 3.7-84.0 | 21.0-50.0 | 14°-20° | * |

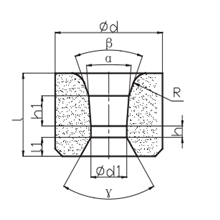

| Dimension |

| ΦD | Φd | H | α | γ | R |

| 16.0-110.0 | 2.0-60.0 | 14-52 | 3° | 60° | 40 |

| 16.0-110.0 | 20.0-62.0 | 35-45 | 4° | 15.0-40.0 |

| 16.0-110.0 | 2.8-88.0 | 13-50 | 24° | 3.0-10.0 |

| 16.0-110.0 | 20.0-70.0 | 32-55 | * | 3.0-40.0 |

| Dimension |

| d | l | A | h | h1 | ll |

| 16 | 12 | 1.5-2.5 | 0.5-1.5 | 4.0-6.0 | 1.0-2.0 |

| 22 | 18 | 2.0-4.0 | 1.0-2.0 | 5.5-9.0 | 1.5-2.5 |

| 30 | 21 | 3.5-7.0 | 1.5-2.5 | 8.0-12.0 | 1.5-2.5 |

| 35 | 25 | 6.5-10.0 | 2.5-3.5 | 10.0-14.0 | 2.0-4.0 |

| 45 | 25 | 8.0-15.0 | 3.0-4.0 | 10.0-14.0 | 2.0-4.0 |

| 50 | 28 | 12.0-20.0 | 3.5-4.5 | 12.0-16.0 | 2.0-4.0 |

| 60 | 30 | 18.0-25.0 | 4.0-5.5 | 12.0-16.0 | 3.0-5.0 |

| 65 | 32 | 22.0-30.0 | 5.0-7.0 | 12.0-16.0 | 4.0-6.0 |

| 70 | 35 | 26.0-35.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 80 | 35 | 30.0-40.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 90 | 40 | 35.0-45.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 100 | 40 | 40.0-50.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 120 | 45 | 45.0-55.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| Note:α=14° 16° 20° β=40° γ=60° |

| Dimension | |

| d | l | A | B | h | h1 | ll |

| 20 | 12 | 1.5-3.5 | 0.5-1.5 | 1.5-2.5 | 3.0-5.0 | 1.5-2.5 |

| 22 | 12 | 3.0-5.0 | 0.5-2.0 | 1.5-2.5 | 3.0-5.0 | 1.5-2.5 |

| 25 | 15 | 3.5-7.0 | 0.5-4.0 | 2.0-3.0 | 4.0-6.0 | 2.0-3.0 |

| 32 | 16 | 5.0-9.0 | 1.5-4.0 | 2.0-3.0 | 4.0-6.0 | 2.0-3.0 |

| 35 | 18 | 7.0-12.0 | 1.0-6.0 | 2.0-3.0 | 5.0-8.0 | 2.0-3.0 |

| 25 | 7.0-12.0 | 2.0-8.0 | 2.5-3.5 | 7.0-13.0 | 2.5-3.5 |

| 45 | 20 | 10.0-15.0 | 1.0-7.0 | 2.5-3.5 | 5.0-8.0 | 2.5-3.5 |

| 25 | 10.0-15.0 | 4.0-10.0 | 3.0-4.0 | 7.0-14.0 | 2.5-3.5 |

| 50 | 20 | 12.0-24.0 | 1.0-8.0 | 2.5-3.5 | 5.0-96.0 | 2.5-3.5 |

| 28 | 12.0-24.0 | 6.0-16.0 | 3.0-4.0 | 8.0-15.0 | 2.5-3.5 |

| 60 | 20 | 18.0-32.0 | 1.0-9.0 | 2.5-4.0 | 5.0-10.0 | 2.5-3.5 |

| 30 | 18.0-32.0 | 7.0-16.0 | 4.0-6.0 | 8.0-16.0 | 3.0-5.0 |

| Note: α=° 14°18° β=40° 60° γ=60° |

Production Process

FAQ

A1: What is your main product?

Q1: The main product include tungsten carbide bar, carbide wire

drawing die, carbide drill bit button, carbide SS10 tips, carbide

strip and carbide plate, anvil, carbide inserts, and any other

carbide products and customized products.

A2: Do you have certification on your products?

Q2: ISO 9001:2018

A3: What is about your general delivery date?

Q3: Normally 7-15 workdays .

A4: What is your packing?

Q4: We use standard export packing and customization is available.

A5: Can I get the samples?

Q5: Sure, contact us directly.