Water Jet Nozzle Cutting Head Parts WaterJet Tungsten Carbide

Nozzle

Advantages of tungsten carbide water jet nozzle:

1. Excellent wear resistance

Density: 15.66g/cm,Rockwell hardness: 96.5 HRA

2. Long service life

Tungsten carbide nozzle are usually considered to be the most

durable of all material types,also carbide has property of

anti-erosion and high temperature.tungsten carbide nozzles are high

precision wear part of hard alloy. They are mainly used to scour

mud and slurry and cool down when the drilling bit is working.

According to different geographic features of prospection, the

design of flow, shape and size is different.According to the

drilling bit, they are mianly classified into "with screw thread"

and "without screw thread". The nozzles without thread are used in

roller cone bit, while the ones with that are applied in PDC drill

bits. Another way, according to the wrenches that is used to

dismantle, they are classified into 4-slots, 3-slots, and

hexagon,inner hexagon and quincunx.Tungsten carbide nozzle is a

must in oil drilling bit because of such features as corrosion

resistance and wear resistance and long life span.Tungsten carbide

high precision wear parts are widely used in other industries apart

from oil drilling, such as steel smelting, coal mining, chemical

industry, machining and so on.

tungsten carbide waterjet nozzles inner tube is high finish blast

hole, and the use of our unique polishing technology pores to keep

the hardness of inside waterjet nozzles is same as the outside of

water jet nozzles. Comparing to other common tungsten water jet

nozzles:higher hardness, higher density, higher wear resistance,

higher stability.Consistent and long service life.

How to choose a tungsten carbide nozzle?

When choosing a tungsten carbide nozzle, consider the amount of

available air in cfm, the capacity of the blast machine and the

inside diameter of the piping, and the blast and air hoses. For

optimal performance, these elements must be compatibly sized.

If too large a nozzle is used, low blast pressure and rapid wear on

the blast hose will occur. If too small a nozzle is used, smooth

media flow will be difficult to achieve.

Grade List

| Grade | Co (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 |

| Grade | Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) |

| XN100 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 1800 |

| XN101 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 2200 |

| XTN10 | 19.5-20.5 | 6.5-7.5 | 90.5-92.0 | 2800 |

| Grade | Co+Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) |

| XTT50 | 14.0-15.0 | 8.9-9.5 | 89.0-91.0 | 1600 |

| XTP10 | 7.0-9.0 | 11.5-13.0 | 89.5-91.0 | 1800 |

Details Of Tumgsten Carbide Nozzle

| Type | Dimension (mm) |

| φC ±0.15 | φA ±0.15 | φB±0.15 | φD ±0.15 |

| XJO1-64 | 6.4 | 20.3 | 15.8 | 6.4 |

| XJO1-71 | 7.1 | 20.3 | 15.8 | 7.1 |

| XJO1-86 | 8.6 | 20.3 | 15.8 | 8.6 |

| XJO1-94 | 9.4 | 20.3 | 15.8 | 9.4 |

| XJO1-109 | 10.9 | 20.3 | 15.8 | 10.9 |

| XJO1-117 | 11.7 | 20.3 | 15.8 | 11.7 |

| XJO1-127 | 12.7 | 20.3 | 15.8 | 12.7 |

| XJO1-142 | 14.2 | 20.3 | 15.8 | 14.2 |

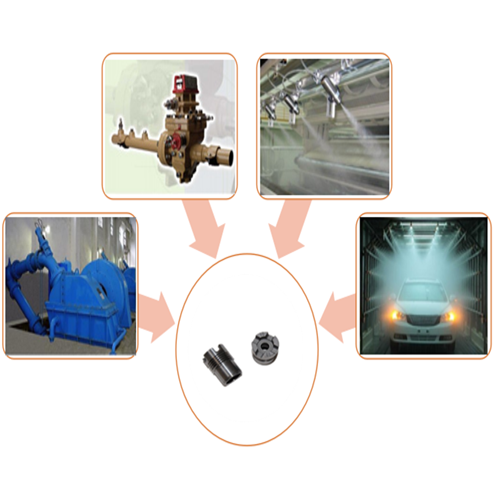

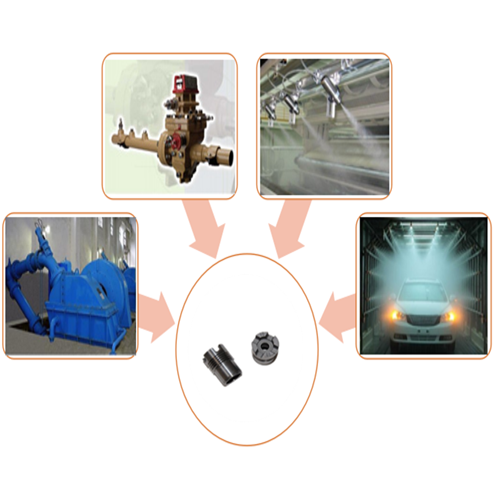

Product Application Scene

Production Process

FAQ

Q1: How can I place order?

A1: You can contact us by email about your order details, or place

order on line.

Q2: How can I pay you?

A2: After you confirm our PI, we will request you to pay. T/T (HSBC

bank) and Paypal, Western Union are the most usual ways we are

using.

Q3: What’s the order procedure?

A3: First we discuss order details, production details by email or

TM. Then we issue you an PI for your confirmation. You will be

requested to do pr -epaid full payment or deposit before we go into

production. After we get the deposit, we start to process the

order. We usually need 7-15 days if we don’t have the items in

stock. Before production has been finished, we will contact you for

shipment details, and the balance payment. After payment has been

settled, we start to prepare the shipment for you.

Q4: How do you take care when your clients received defective

products?

A4: replacement. If there are some defective items, we usually

credit to our customer or replace in next shipment.

Q5: How do you check all the goods in the production line?

A5: We have spot inspection and finished product inspection. We

check the goods when they go into next step production procedure.