Customized Highly Compressed Tungsten Carbide Sandblasting Nozzles

Water Jet Cutting is an industrial manufacturing technique that

uses a very highly pressurized stream of water to cut through

rubber, foam, plastics, leather, composites, stone, tile, metals,

food, paper, aluminum, and more.The water stream is usually mixed

with an abrasive powder, but pure water can be used when cutting

softer materials.

Advantages of tungsten carbide water jet nozzle

1. Excellent wear resistance

Density: 15.66g/cm,Rockwell hardness: 96.5 HRAWater Jet Cutting is

an industrial manufacturing technique that uses a very highly

pressurizedstream of water to cut through rubber, foam, plastics,

leather, composites, stone, tile, metals, food, paper, aluminum,

and more.The water stream is usually mixed with an abrasive powder,

but pure water can be used when cutting softer materials.

2. Long service life

Tungsten carbide nozzle are usually considered to be the most

durable of all material types,also carbide has property of

anti-erosion and high temperature.tungsten carbide nozzles are high

precision wear part of hard alloy. They are mainly used to scour

mud and slurry and cool down when the drilling bit is working.

According to different geographic features of prospection, the

design of flow, shape and size is different.According to the

drilling bit, they are mianly classified into "with screw thread"

and "without screw thread". The nozzles without thread are used in

roller cone bit, while the ones with that are applied in PDC drill

bits. Another way, according to the wrenches that is used to

dismantle, they are classified into 4-slots, 3-slots, and

hexagon,inner hexagon and quincunx.Tungsten carbide nozzle is a

must in oil drilling bit because of such features as corrosion

resistance and wear resistance and long life span.Tungsten carbide

high precision wear parts are widely used in other industries apart

from oil drilling, such as steel smelting, coal mining, chemical

industry, machining and so on.

tungsten carbide waterjet nozzles inner tube is high finish blast

hole, and the use of our unique polishing technology pores to keep

the hardness of inside waterjet nozzles is same as the outside of

water jet nozzles. Comparing to other common tungsten water jet

nozzles:higher hardness, higher density, higher wear resistance,

higher stability.Consistent and long service life.

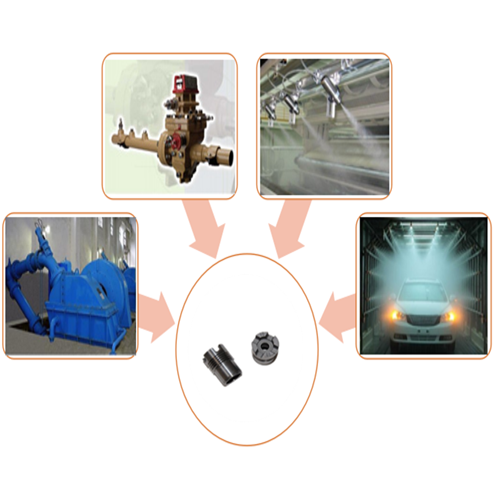

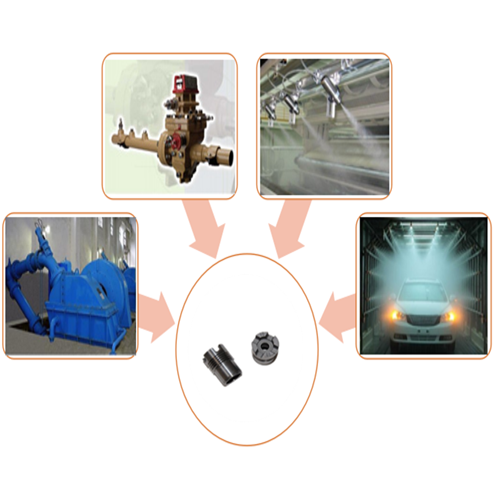

Application

The cemented carbide nozzles will be used mainly to PDC drill bits

and roller core flushing, drill bits for cooling and lubricationg

drill bit tips and cleaning stone chips in the well bottom with

drilling liguid in the working conditions of high pressure,

vibration, sand and slurry impacting during oil and natural gas

prospecting.

Main Products

Cross groove thread nozzles, plum blossom type thread nozzles,

outer hexagonal thread nozzles, internal hexagonal thread nozzles,

Y type(three grooves) thread nozzles, gear wheel drill bitt nozzles

and press fracturing nozzles, there are various sizes and types of

the products. We can recommend, design, develop, produce and supply

the products according to the drawings and requirements of the

customers.

The tungsten carbide bearing parts adopts the advance technology

with the high strength and long life features. The cemented carbide

bearing surface with the cemented carbide material, special solder

and welded to a whole body with the basis part through sinter

treatment, makes the cemented carbide bearing with the high

strength, long life, anti-wear, anti-impact and high load.

Grade List

| Grade | Co (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 |

| Grade | Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) |

| XN100 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 1800 |

| XN101 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 2200 |

| XTN10 | 19.5-20.5 | 6.5-7.5 | 90.5-92.0 | 2800 |

| Grade | Co+Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) |

| XTT50 | 14.0-15.0 | 8.9-9.5 | 89.0-91.0 | 1600 |

| XTP10 | 7.0-9.0 | 11.5-13.0 | 89.5-91.0 | 1800 |

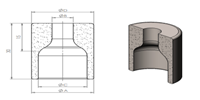

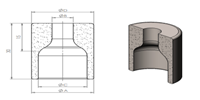

Details Of Tumgsten Carbide Nozzle

| Type | Dimension (mm) |

| φC ±0.15 | φA ±0.15 | φB±0.15 | φD ±0.15 |

| XJO1-64 | 6.4 | 20.3 | 15.8 | 6.4 |

| XJO1-71 | 7.1 | 20.3 | 15.8 | 7.1 |

| XJO1-86 | 8.6 | 20.3 | 15.8 | 8.6 |

| XJO1-94 | 9.4 | 20.3 | 15.8 | 9.4 |

| XJO1-109 | 10.9 | 20.3 | 15.8 | 10.9 |

| XJO1-117 | 11.7 | 20.3 | 15.8 | 11.7 |

| XJO1-127 | 12.7 | 20.3 | 15.8 | 12.7 |

| XJO1-142 | 14.2 | 20.3 | 15.8 | 14.2 |

| Type | |

| φB | φA(φD) | φC |

| XJ02-64 | 6.4 | 18.8 | 14.73 |

| XJ02-71 | 7.1 | 18.8 | 14.73 |

| XJ02-86 | 8.6 | 18.8 | 14.73 |

| XJ02-94 | 9.4 | 18.8 | 14.73 |

| XJ02-109 | 10.9 | 18.8 | 14.73 |

| XJ02-117 | 11.7 | 18.8 | 14.73 |

| XJ02-127 | 12.7 | 18.8 | 14.73 |

| Type | Dimension (mm) |

| φA ±0.25 | φB ±0.25 | φC ±0.25 | φD ±0.20 | φE ±0.20 | F ±1 | G ±1 | M ±1 | K ±0.5 |

| XP01-1 | 24.5 | 30.0 | 5.0 | 9.0 | 18.0 | 50.0 | 69.0 | 21.0 | 130.0 |

| XP01-2 | 24.5 | 30.0 | 8.0 | 12.5 | 20.0 | 50.0 | 69.0 | 21.0 | 140.0 |

| XP01-3 | 24.5 | 30.0 | 10.0 | 13.5 | 21.0 | 50.0 | 69.0 | 21.0 | 170.0 |

| XP01-4 | 24.5 | 30.0 | 13.0 | 19.5 | 27.0 | 50.0 | 69.0 | 21.0 | 226.0 |

| XP01-5 | 30.0 | 36.0 | 6.5 | 12.5 | 19.5 | 54.0 | 70.0 | 20.0 | 130.4 |

| XP01-6 | 30.0 | 36.0 | 8.0 | 12.5 | 12.5 | 54.0 | 70.0 | 20.0 | 141.0 |

| XP01-7 | 30.0 | 36.0 | 11.0 | 15.0 | 12.5 | 55.0 | 69.0 | 21.0 | 200.0 |

| Type | Dimension (mm) |

| φA ±0.25 | φB ±0.25 | φC ±0.20 | φD ±0.20 | φE ±0.25 | F ±2 | K ±0.5 |

| XP02-1 | 32.0 | 25.0 | 6.2 | 8.0 | 16.0 | 45.0 | 78.0 |

| XP02-2 | 32.0 | 25.0 | 8.0 | 10.0 | 18.0 | 45.0 | 78.0 |

| XP02-3 | 32.0 | 25.0 | 11.0 | 13.0 | 21.0 | 45.0 | 78.0 |

| XP02-4 | 38.0 | 32.0 | 6.2 | 6.2 | 16.0 | 45.0 | 80.0 |

| XP02-5 | 38.0 | 32.0 | 8.0 | 8.0 | 18.0 | 45.0 | 80.0 |

Product Application Scene

Production Process

FAQ

Q1: Is Xingyu trading company or manufacturer ?

A1: We are manufacture of tungsten carbide since established on

1998,specializing in carbide plates/bushings/rollers/special wear

parts.

Q2: Has Xingyu acquired the foremost certification of ISO 9001?

A2: Xingyu has been endorsed with the ISO 9001 rating since 2008.

Q3: When can I get the offer after sending inquiry?

A3: We usually quote within 24 hours after we get your inquiry .If

you are very urgent to get the price please call us or tell us in

your email so that we will regard your inquiry priority.

.

Q4: Could Xingyu sales staff be reached anytime for assistance

regarding orders or general enquire ?

A4: Our sales staff operates between 8am-5pm Monday to Saturday.