Customized Size Hole Diameter Tungsten Carbide Wire Drawing Dies

Wire drawing molds are widely used, such as electronic devices,

radar, television, instruments and aerospace and other

high-precision wire, as well as commonly used tungsten wire,

molybdenum wire, stainless steel wire. Wire cable wire and all

kinds of alloy wire are drawn by diamond drawing die. The diamond

drawing die has extremely strong wear resistance and long service

life because of the use of natural diamond as raw material.

Applications

1. Automotive industry

2. Construction and metal construction industry

3. Electric and electronic industry

4. Jewellery industry

5.Tube and profile drawing tools

6. Bar drawing

Grade List

| Grade | Co (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Applications |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 | Wire drawing dies for wear-resistance impact-resistance |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 |

| XC300 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 2600 |

| XC301 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 3200 |

| XC500 | 14.7-15.3 | 13.9-14.2 | 87.0-88.0 | 2600 | Stamping dies for impact-resistance |

| XC501 | 14.7-15.3 | 13.9-14.2 | 87.0-88.0 | 2800 |

| XC800 | 19.5-20.5 | 13.4-13.6 | 83.0-84.0 | 2600 |

| XC8001 | 19.5-20.5 | 13.4-13.6 | 83.0-84.0 | 3000 |

| XC900 | 23.0-23.5 | 13.1-13.4 | 82.5-83.5 | 2400 |

| XC901 | 23.0-23.5 | 13.1-13.4 | 82.5-83.5 | 2600 |

| Grade | Co+Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Applications |

| XCN61 | 16.0-17.0 | 13.5-14.0 | 83.5-84.5 | 3200 | Stamping dies for High temperature-resistance |

| XCN71 | 17.0-18.0 | 13.3-13.8 | 82.0-83.0 | 3000 |

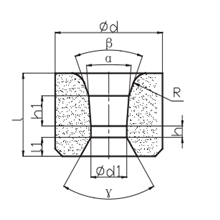

| Dimension |

| d | l | d1 | h | h1 | ll |

| 8 | 6 | 0.1-1.0 | 0.1-10.6 | 1.0-2.0 | 0.8-1.2 |

| 10 | 8 | 0.1-1.2 | 0.1-0.8 | 1.5-4.0 | 1.0-1.8 |

| 12 | 10 | 0.2-2.0 | 0.1-1.5 | 2.0-5.0 | 1.6-2.5 |

| 14 | 12 | 0.4-2.5 | 0.2-2.0 | 4.0-5.0 | 1.8-2.5 |

| 16 | 13 | 0.5-3.0 | 0.2-2.5 | 4.0-5.5 | 2.0-3.0 |

| 20 | 17 | 1.0-6.0 | 0.6-3.0 | 5.0-8.0 | 2.5-4.0 |

| 25 | 20 | 2.0-8.5 | 1.0-3.5 | 7.0-10.0 | 3.0-4.5 |

| 30 | 24 | 3.5-12.0 | 2.0-4.0 | 8.0-12.0 | 3.0-5.0 |

| Notice: α=8°10° 12° 14°16°18° β=40° 60° 90° γ=60° 75° 90° |

| Dimension | |

| ΦD | b | H | α | β | γ |

| 6.0-8.0 | 0..2 | 4.0-6.0 | 10° | 40° | 60° |

| 6.0-8.0 | 0.4-0.8 | 4.0-6.0 | 40° | * |

| 8.0-22.0 | 0.4-5.7 | 6.0-20.0 | 10°-14° | 40° |

| 8.0-26.0 | 0.4-8.0 | 6.0-16.0 | 16° | 40° |

| 30.0-140.0 | 3.7-84.0 | 21.0-50.0 | 14°-20° | * |

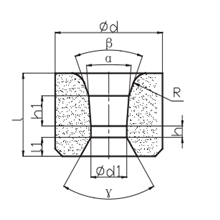

| Dimension |

| ΦD | Φd | H | α | γ | R |

| 16.0-110.0 | 2.0-60.0 | 14-52 | 3° | 60° | 40 |

| 16.0-110.0 | 20.0-62.0 | 35-45 | 4° | 15.0-40.0 |

| 16.0-110.0 | 2.8-88.0 | 13-50 | 24° | 3.0-10.0 |

| 16.0-110.0 | 20.0-70.0 | 32-55 | * | 3.0-40.0 |

| Dimension |

| d | l | A | h | h1 | ll |

| 16 | 12 | 1.5-2.5 | 0.5-1.5 | 4.0-6.0 | 1.0-2.0 |

| 22 | 18 | 2.0-4.0 | 1.0-2.0 | 5.5-9.0 | 1.5-2.5 |

| 30 | 21 | 3.5-7.0 | 1.5-2.5 | 8.0-12.0 | 1.5-2.5 |

| 35 | 25 | 6.5-10.0 | 2.5-3.5 | 10.0-14.0 | 2.0-4.0 |

| 45 | 25 | 8.0-15.0 | 3.0-4.0 | 10.0-14.0 | 2.0-4.0 |

| 50 | 28 | 12.0-20.0 | 3.5-4.5 | 12.0-16.0 | 2.0-4.0 |

| 60 | 30 | 18.0-25.0 | 4.0-5.5 | 12.0-16.0 | 3.0-5.0 |

| 65 | 32 | 22.0-30.0 | 5.0-7.0 | 12.0-16.0 | 4.0-6.0 |

| 70 | 35 | 26.0-35.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 80 | 35 | 30.0-40.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 90 | 40 | 35.0-45.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 100 | 40 | 40.0-50.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| 120 | 45 | 45.0-55.0 | 6.0-9.0 | 14.0-18.0 | 5.0-7.0 |

| Note:α=14° 16° 20° β=40° γ=60° |

| Dimension | |

| d | l | A | B | h | h1 | ll |

| 20 | 12 | 1.5-3.5 | 0.5-1.5 | 1.5-2.5 | 3.0-5.0 | 1.5-2.5 |

| 22 | 12 | 3.0-5.0 | 0.5-2.0 | 1.5-2.5 | 3.0-5.0 | 1.5-2.5 |

| 25 | 15 | 3.5-7.0 | 0.5-4.0 | 2.0-3.0 | 4.0-6.0 | 2.0-3.0 |

| 32 | 16 | 5.0-9.0 | 1.5-4.0 | 2.0-3.0 | 4.0-6.0 | 2.0-3.0 |

| 35 | 18 | 7.0-12.0 | 1.0-6.0 | 2.0-3.0 | 5.0-8.0 | 2.0-3.0 |

| 25 | 7.0-12.0 | 2.0-8.0 | 2.5-3.5 | 7.0-13.0 | 2.5-3.5 |

| 45 | 20 | 10.0-15.0 | 1.0-7.0 | 2.5-3.5 | 5.0-8.0 | 2.5-3.5 |

| 25 | 10.0-15.0 | 4.0-10.0 | 3.0-4.0 | 7.0-14.0 | 2.5-3.5 |

| 50 | 20 | 12.0-24.0 | 1.0-8.0 | 2.5-3.5 | 5.0-96.0 | 2.5-3.5 |

| 28 | 12.0-24.0 | 6.0-16.0 | 3.0-4.0 | 8.0-15.0 | 2.5-3.5 |

| 60 | 20 | 18.0-32.0 | 1.0-9.0 | 2.5-4.0 | 5.0-10.0 | 2.5-3.5 |

| 30 | 18.0-32.0 | 7.0-16.0 | 4.0-6.0 | 8.0-16.0 | 3.0-5.0 |

| Note: α=° 14°18° β=40° 60° γ=60° |

Production Process

FAQ

Q1: How can I place order?

A1: You can contact us by email about your order details, or place

order on line.

Q2: How can I pay you?

A2: After you confirm our PI, we will request you to pay. T/T (HSBC

bank) and Paypal, Western Union are the most usual ways we are

using.

Q3: What’s the order procedure?

A3: First we discuss order details, production details by email or

TM. Then we issue you an PI for your confirmation. You will be

requested to do pr -epaid full payment or deposit before we go into

production. After we get the deposit, we start to process the

order. We usually need 7-15 days if we don’t have the items in

stock. Before production has been finished, we will contact you for

shipment details, and the balance payment. After payment has been

settled, we start to prepare the shipment for you.

Q4: How do you take care when your clients received defective

products?

A4: replacement. If there are some defective items, we usually

credit to our customer or replace in next shipment.

Q5: How do you check all the goods in the production line?

A5: We have spot inspection and finished product inspection. We

check the goods when they go into next step production procedure.