Excellent Performance Tungsten Carbide Wire Drawing Die

Mould characteristics

1. Special pretreatment technology creates super strong film base

bonding force and prolongs die life.

2. Ultra long life, greatly reducing the mold changing frequency.

3. Ultra fine nano polishing surface to improve wire quality.

4. Improve drawing rate, achieve super high speed drawing and

improve production efficiency.

5. Without special cooling, water cooling can ensure super long

life.

6. Without special lubrication, clean and lubricated medium can

realize super long service of mould.

Advantage

1. This tungsten carbide mold is in high precision,whose tolerance

can be +/-0.002mm.

2. For the shape,size,material etc. is made by customers' needs and

requirements.

3. This carbide die with coating can be used for much longer time

than steel die.

4. It has many advantages such as Wear resistant, Heat resistant

and Corrosion resistant.

Grade List

| Grade | Co (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Applications |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 | Wire drawing dies for wear-resistance impact-resistance |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 |

| XC300 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 2600 |

| XC301 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 3200 |

| XC500 | 14.7-15.3 | 13.9-14.2 | 87.0-88.0 | 2600 | Stamping dies for impact-resistance |

| XC501 | 14.7-15.3 | 13.9-14.2 | 87.0-88.0 | 2800 |

| XC800 | 19.5-20.5 | 13.4-13.6 | 83.0-84.0 | 2600 |

| XC8001 | 19.5-20.5 | 13.4-13.6 | 83.0-84.0 | 3000 |

| XC900 | 23.0-23.5 | 13.1-13.4 | 82.5-83.5 | 2400 |

| XC901 | 23.0-23.5 | 13.1-13.4 | 82.5-83.5 | 2600 |

| Grade | Co+Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Applications |

| XCN61 | 16.0-17.0 | 13.5-14.0 | 83.5-84.5 | 3200 | Stamping dies for High temperature-resistance |

| XCN71 | 17.0-18.0 | 13.3-13.8 | 82.0-83.0 | 3000 |

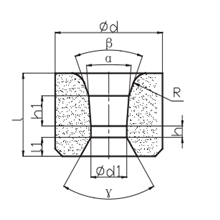

| Dimension |

| d | l | d1 | h | h1 | ll |

| 8 | 6 | 0.1-1.0 | 0.1-10.6 | 1.0-2.0 | 0.8-1.2 |

| 10 | 8 | 0.1-1.2 | 0.1-0.8 | 1.5-4.0 | 1.0-1.8 |

| 12 | 10 | 0.2-2.0 | 0.1-1.5 | 2.0-5.0 | 1.6-2.5 |

| 14 | 12 | 0.4-2.5 | 0.2-2.0 | 4.0-5.0 | 1.8-2.5 |

| 16 | 13 | 0.5-3.0 | 0.2-2.5 | 4.0-5.5 | 2.0-3.0 |

| 20 | 17 | 1.0-6.0 | 0.6-3.0 | 5.0-8.0 | 2.5-4.0 |

| 25 | 20 | 2.0-8.5 | 1.0-3.5 | 7.0-10.0 | 3.0-4.5 |

| 30 | 24 | 3.5-12.0 | 2.0-4.0 | 8.0-12.0 | 3.0-5.0 |

| Notice: α=8°10° 12° 14°16°18° β=40° 60° 90° γ=60° 75° 90° |

| Dimension | |

| ΦD | b | H | α | β | γ |

| 6.0-8.0 | 0..2 | 4.0-6.0 | 10° | 40° | 60° |

| 6.0-8.0 | 0.4-0.8 | 4.0-6.0 | 40° | * |

| 8.0-22.0 | 0.4-5.7 | 6.0-20.0 | 10°-14° | 40° |

| 8.0-26.0 | 0.4-8.0 | 6.0-16.0 | 16° | 40° |

| 30.0-140.0 | 3.7-84.0 | 21.0-50.0 | 14°-20° | * |

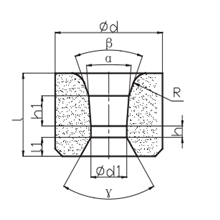

| Dimension |

| ΦD | Φd | H | α | γ | R |

| 16.0-110.0 | 2.0-60.0 | 14-52 | 3° | 60° | 40 |

| 16.0-110.0 | 20.0-62.0 | 35-45 | 4° | 15.0-40.0 |

| 16.0-110.0 | 2.8-88.0 | 13-50 | 24° | 3.0-10.0 |

| 16.0-110.0 | 20.0-70.0 | 32-55 | * | 3.0-40.0 |

Production Process

FAQ

Q1: How long is your delivery period?

A1: It depends on specific conditions. However, it could be 10 to

15 days on average.

Q2: Do you offer samples?

A2: Yes, we do offer samples. However, buyers need to pay for the

freight charge. In addition, whether samples are free or not

depends on the quantity you buy.

Q3: How do you pack the products?

A3: In general, we use wood, plastic or carton boxes. We also put

some soft materials inside to prevent possible damage on products.

Q4: How much advance payment do I need to make?

A4: If the products you buy are in stock, you need to make full

payment; if the products are out of stock, you need to make about

50 percent of full payment and then we will start the production

process. However, you still need to pay the rest of charges before

we deliver the products.

Q5: What kinds of payment do you accept?

A5: In addition to the patterns of payment shown above, you can

discuss with us about in which way you would like to pay.

Please contact us if you have any other questions.