Customizing Wear Tungsten Carbide Bush / Bearing Bushing / Thrust

Sleeve

The Product Application of tungsten carbide bushing

Tungsten carbide bushing applications is widely, which is a device

to protect a class of components. It is in the actual work and the

role and purpose of its application environment have a great

relationship. Valve applications, bushings be installed in the

valve stem cap trap, in order to reduce the valve leakage, to seal;

bearing applications, the use of bush to reduce wear between the

bearing and the shaft seat, avoid the gap between the shaft and the

hole increases and so on.

Tungsten carbide bushing production and processing of

high-strength, can withstand prolonged load, with high chemical

stability, alkali, alcohol, ether, hydrocarbons, acid, oil,

detergent, water (sea water), and has no smell , non-toxic,

tasteless, non-rust characteristics, its widely used in

petrochemical industry for Submerged Oil Pump, slurry pump, water

pump, Centrifugal Pump,etc.

The Product feature of tungsten carbide bushing

1. High hard resistance

2. High corrosion resistance

3. Pressured resistance

4. Wear resistance

5. High bending strength

Grade List

Grade | Density | T.R.S. MPa | Performance & application recommended |

YG6A | 14.95 | 1800 | Fine grain alloy, good wear resistance. Semi-finishing of chilled

cast iron, non-ferrous metals alloys, semi-finishing and finishing

of hardened steel, alloy steel. |

YG8 | 14.8 | 2200 | High strength in use, impact and shock resistance higher than YG6,

but wear resistance and cutting speed comparatively lower |

YN8 | 14.7 | 2000 | Corrosion Resistant, It widely used in chemical and petroleum pumps |

YG10 | 14.5 | 2400 | High strength in use, impact and shock resistance higher than YG6,

but wear resistance and cutting speed comparatively lower. Roughing

of cast irons, non-ferrous metals and their alloys as well as non

metallic materials at low cutting speed. |

YL10.2 | 14.5 | 2400 | Fine grain alloy, good wear resistance. Used for processing hard

wood, veneer board, PCB, PVC and metals |

YG20 | 14.3 | 2420 | Conventional wear resistance, high bending strength,used for steel

alloy etc. |

Details Carbide Bushing

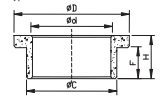

| Deimensions of A Type Straight Sleeves (mm) |

|

| D | d | C | F | H |

| 13.0-59.0 | 3.0-51.0 | 8.0-556.0 | 22.5 | 25.5 |

| 35.0-51.0 | 22.0-37.0 | 28.0-41.0 | 11.0-16.0 | 15.0-25.0 |

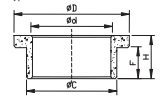

| Deimensions of A Type Straight Sleeves (mm) |

|

| D | d | C | F | H |

| 38.0-50.0 | 35.0-45.0 | 30.0-35.0 | 20.0-30.0 | 27.0-40.0 |

| 51.0-100.0 | 46.0-95.0 | 35.0-80.0 | 20.0-30.0 | 30.0-50.0 |

Product Application Scene

Production Process

FAQ

Q1: How can I place order?

A1: You can contact us by email about your order details, or place

order on line.

Q2: How can I pay you?

A2: After you confirm our PI, we will request you to pay. T/T (HSBC

bank) and Paypal, Western Union are the most usual ways we are

using.

Q3: What’s the order procedure?

A3: First we discuss order details, production details by email or

TM. Then we issue you an PI for your confirmation. You will be

requested to do pr -epaid full payment or deposit before we go into

production. After we get the deposit, we start to process the

order. We usually need 7-15 days if we don’t have the items in

stock. Before production has been finished, we will contact you for

shipment details, and the balance payment. After payment has been

settled, we start to prepare the shipment for you.

Q4: How do you take care when your clients received defective

products?

A4: replacement. If there are some defective items, we usually

credit to our customer or replace in next shipment.

Q5: How do you check all the goods in the production line?

A5: We have spot inspection and finished product inspection. We

check the goods when they go into next step production procedure.