Standard Polished Tungsten Carbide Bushes Corrosion Resistance

Carbide Sleeve

The Benifits Of Useing Carbide Bushings

A durable, industrial steel, carbide is used to make parts in a

variety of machining applications. Also known as tungsten carbide,

this essential element contains equal parts tungsten and carbon

atoms, making it one of the strongest metals on Earth. For this

reason, carbide is often applied to bushings, dies, gages and other

machining parts. Explore the benefits that carbide bushings have to

offer below, and then Us to see what we can do for you.

Carbide bushings are resistant to wear

Tungsten is known for its high melting point and durability. It’s

also resistant to corrosion, which is ideal for industrial and

manufacturing use. Likewise, bushings made from carbide offer an

outstanding shelf life. That means you’ll spend less time switching

out worn-down bushings, and more time getting the job done.

Application of tungsten carbide sleeve/bushing

Tungsten carbide bushing applications is widely, which is a device

to protect important components. In actual working, it have a great

relationship between the rule and application environment.

Valve applications as sealing parts :bushings be installed in the

valve stem cap trap, in order to reduce the valve leakage, for

sealing;

bearing applications as protecting parts:the use of bush to reduce

wear between the bearing and the shaft seat, avoid the gap between

the shaft and the hole increases and so on.

Tungsten carbide bushing production and processing of

high-strength, can withstand prolonged load, with high chemical

stability, alkali,alcohol,hydrocarbons, acid, oil, detergent, water

(sea water), and has no smell , non-toxic, tasteless, non-rust

characteristics, its widely used in petrochemical industry for

Submerged Oil Pump, slurry pump, water pump, Centrifugal Pump,etc.

Grade List

| Grade | ISO Code | Chemical Composition(%) | Physical Mechanical Properties (≥) | Application |

|

| WC | Co | Density g/cm3 | Hardness(HRA) | T.R.S N/mm2 |

|

| YG3 | K01 | 97 | 3 | 14.90 | 91.00 | 1180 | Suitable for finishing of cast iron,non-ferrous metals,alloys and

non-metallic materials,and semi-finishing vehicles for intermittent

cutting. |

| YG6 | K10 | 94 | 6 | 15.10 | 92.00 | 1420 | Finishing of chilled hard alloy cast iron and heat resistant alloy

steel and ordinary cast iron. |

| YG6X | K20 | 94 | 6 | 15.10 | 91.00 | 1600 | Cast iron, non-ferrous metals and alloys, non-metallic materials,

medium to cutting, semi-finishing and finishing. |

| YG8 | K20-K30 | 92 | 8 | 14.90 | 90.00 | 1600 | Suitable for casting of cast iron, non-ferrous metals and their

alloys and non-metallic materials, roughing of sections and rough

cutting. |

| YG10 | K40 | 90 | 10 | 14.70 | 89.00 | 1900 | Suitable for the production of drawing dies, wear parts and

stamping parts and cores for hard alloy automatic presses. |

| YG10X | K40 | 89 | 10 | 14.70 | 89.50 | 2200 | Suitable for small diameter micro drills, end mills, rotary boring

tools, etc. |

| YG15 | K30 | 85 | 15 | 14.70 | 87.00 | 2100 | Forging, perforating and stamping tools for steel bars and steel

tubes with high compression ratios and working under large

stresses. |

| YG20 | K30 | 80 | 20 | 13.70 | 85.50 | 2500 | Stamping die, stamping watch parts, musical instrument spring

piece. |

| YG20C | K40 | 80 | 20 | 13.70 | 82.00 | 2200 | punching battery case, toothpaste skin mold, small size steel ball,

screw, nut stamping die, hot rolling twist drill bit plate. |

| YG30 | G60 | 70 | 30 | 12.80 | 82.00 | 2750 | Production of standard parts, bearings, tools and other industries

for cold heading, cold punching, cold pressing die. |

Details Carbide Bushing

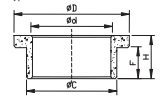

| Deimensions of A Type Straight Sleeves (mm) |

|

| D | d | C | F | H |

| 13.0-59.0 | 3.0-51.0 | 8.0-56.0 | 22.5 | 25.5 |

| 35.0-51.0 | 22.0-37.0 | 28.0-41.0 | 11.0-13.0 | 15.0-25.0 |

| Notice:a=1.6, 3.2 |

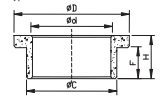

| Deimensions of A Type Straight Sleeves (mm) |

|

| D | d | C | F | H |

| 13.0-59.0 | 3.0-51.0 | 8.0-556.0 | 22.5 | 25.5 |

| 35.0-51.0 | 22.0-37.0 | 28.0-41.0 | 11.0-16.0 | 15.0-25.0 |

Product Application Scene

Production Process

FAQ

Q1: Can I negotiate the Prices?

A1: Yes.

Q1: What is your minimum order requirement?

A1: We accept the sample and trial order.

Q1: How long will it take to execute my order?

A1: For the stock items, we can arrange the shipment within 3-5

days after received your payment.

Q3: Can you give warranty of your products?

A3: Yes, we extend a 100% satisfaction guarantee on all items. The

detailed inspection pictures and the report of the order will be

sent to you for confirmation before delivery. For the overseas

orders, if there is quality problem, please kind to provide the

pictures to show the problems by e-mail . We will provide the

replacements to you at our cost according to actual conditions.